|

|

|

|

OPC 10000-15 |

|

|

OPC Unified Architecture Part 15: Safety

Release 1.05.04 2024-10-15

|

|

|

|

|

OPC 10000-15 |

|

|

OPC Unified Architecture Part 15: Safety

Release 1.05.04 2024-10-15

|

|

Standard Type: |

Industry Standard Specification |

Comments: |

|||

|

|

|

|

|

||

|

Document |

OPC 10000-15 |

|

|

||

|

Title: |

OPC Unified

Architecture |

Date: |

2024-10-15 |

||

|

|

|

|

|

||

|

Version: |

Release 1.05.04 |

Software: |

MS-Word |

||

|

Editors: |

|

Source: |

OPC 10000-15 - UA Specification Part 15 - Safety 1.05.04.docx |

||

|

|

|

|

|

||

|

Owner: |

OPC Foundation and PROFIBUS Nutzerorganisation e.V. |

Status: |

|

||

|

|

|

|

|

||

CONTENTS

3 Terms, definitions, symbols, abbreviated terms and conventions

3.1.1 Common terms and definitions

3.1.2 Additional terms and definitions

3.2 Symbols and abbreviated terms

3.2.1 Abbreviated terms from IEC 61784-3

3.2.2 Additional symbols and abbreviated terms

3.3.2 Conventions for requirements numbering

3.3.3 Conventions in state machines

5.1 External documents providing specifications for the profile

5.2 Safety functional requirements

5.4 Safety communication layer structure

5.5 Requirements for CRC calculation

6 Safety communication layer services

6.2.2 Object and ObjectType Definitions

6.2.5 DataTypes and length of SafetyData

6.2.6 Connection establishment

6.3.2 OPC UA Platform interface (OPC UA PI)

6.3.3 SafetyProvider interfaces

6.3.4 SafetyConsumer interfaces

6.3.5 Cyclic and acyclic safety communication

6.3.6 Principle for “application variables with qualifier”

6.4.2 Diagnostics messages of the SafetyConsumer

6.4.3 Method ReadSafetyDiagnostics of the SafetyProvider

7 Safety communication layer protocol

7.2 SafetyProvider and SafetyConsumer

8 Safety communication layer management

8.2 Safety function response time part of communication

9 System requirements (SafetyProvider and SafetyConsumer)

9.1 Constraints on the SPDU parameters

9.1.1 SafetyBaseID and SafetyProviderID

9.2 Initialization of the MNR in the SafetyConsumer

9.3 Constraints on the calculation of system characteristics

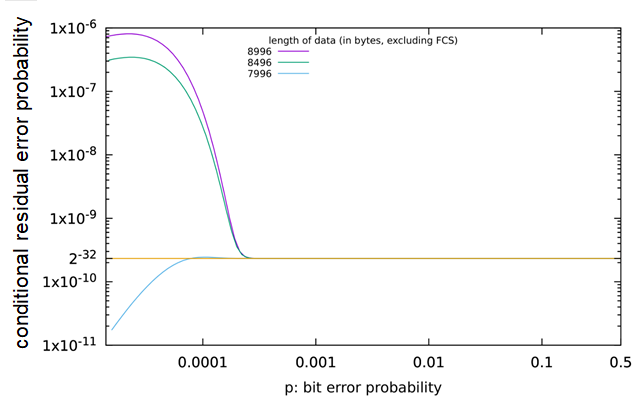

9.3.1 Probabilistic considerations (informative)

9.3.2 Safety related assumptions (informative)

9.4 PFH and PFD values of a logical safety communication link

10.3 Index of requirements (informative)

11 Profiles and Conformance Units

12.2 Handling of OPC UA namespaces

Annex A (normative) Safety Namespace and mappings

Annex B (informative) Additional information.

B.1 CRC calculation using tables, for the polynomial 0xF4ACFB13

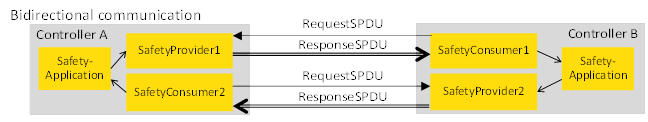

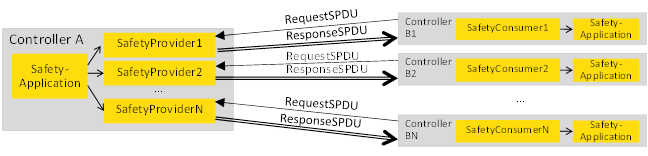

B.2.1 Unidirectional communication

B.2.2 Bidirectional communication

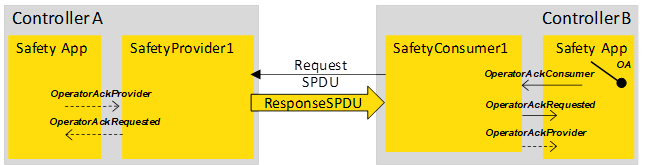

B.3 Use cases for Operator Acknowledgment

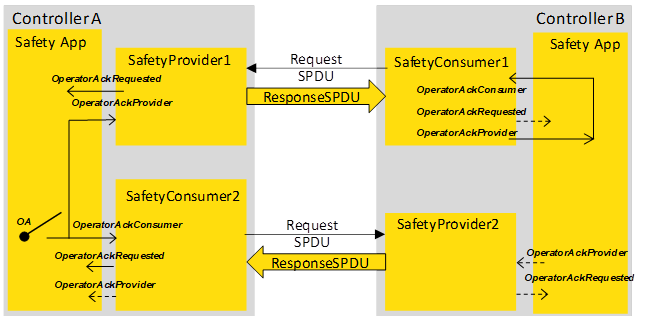

B.3.2 Use case 1: unidirectional communication and OA on the SafetyConsumer side

B.3.3 Use case 2: bidirectional communication and dual OA

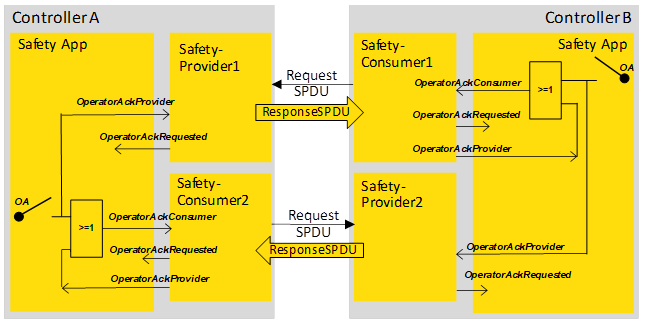

B.3.4 Use case 3: bidirectional communication and single, one-sided OA

B.3.5 Use case 4: bidirectional communication and single, two-sided OA

Annex C (informative) Information for assessment

Figure 1 (informative) – Relationships of OPC UA Safety with other standards.................. xi

Figure 5 – Safety multicast with three recipients using IEC 62541 PubSub...................... 21

Figure 6 – Safety parameters for the SafetyProvider and the SafetyConsumer.................. 22

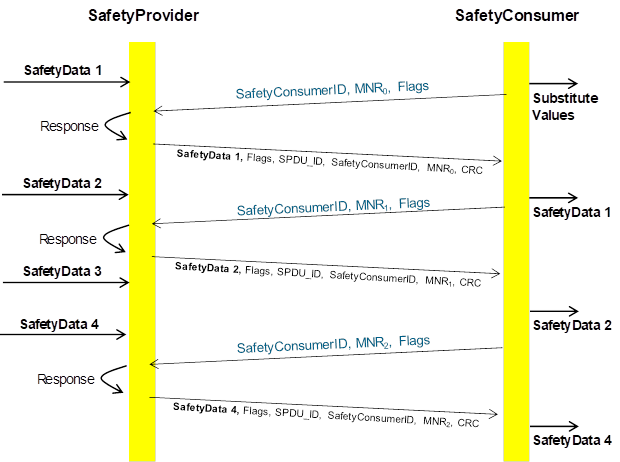

Figure 13 (informative) – Sequence diagram for requests and responses (Client/Server)..... 47

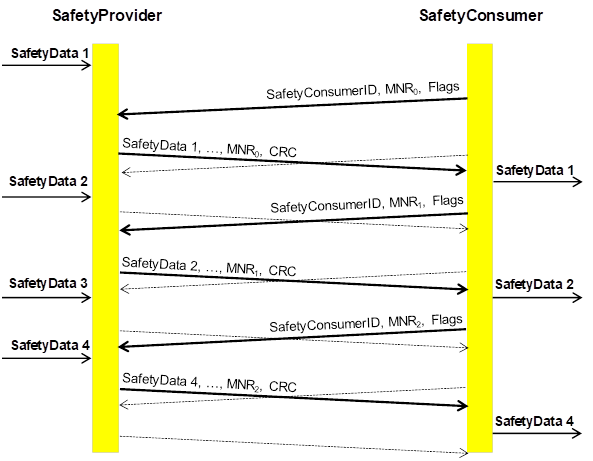

Figure 14 (informative) – Sequence diagram for requests and responses (PubSub)........... 48

Figure 17 – Simplified representation of the state diagram for the SafetyProvider.............. 50

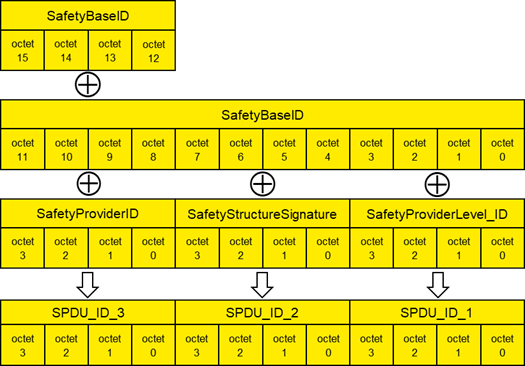

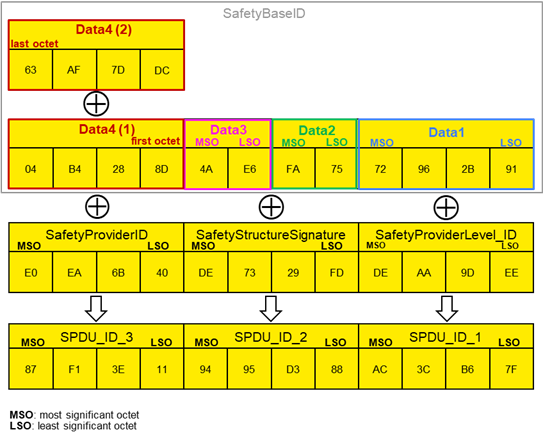

Figure 22 (informative) – Example for the calculation of SPDU_ID_1, SPDU_ID_2 and SPDU_ID_3 65

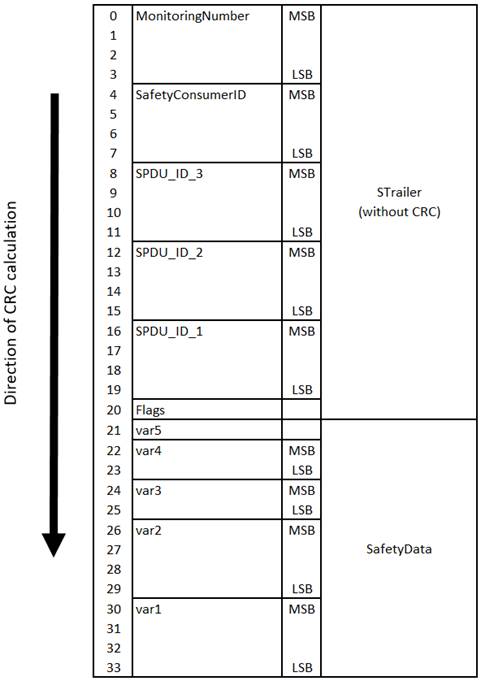

Figure 23 – Calculation of the CRC (on little-endian machines, CRC32_Backward)............ 68

Figure 24 – Calculation of the CRC (on big-endian machines, CRC32_Forward)............... 69

Figure 27 – Counter example: data lengths not supported by OPC Safety....................... 75

Figure B.5 – Two-sided OA in bidirectional safety communication.................................. 88

Figure B.6 – One sided OA in bidirectional safety communication.................................. 88

Table 2 – Deployed safety measures to detect communication errors............................... 9

Table 8 – ReadSafetyData Method AddressSpace definition........................................ 18

Table 9 – ReadSafetyDiagnostics Method arguments................................................. 19

Table 10 – ReadSafetyDiagnostics Method AddressSpace definition.............................. 20

Table 13 – SafetyConsumerParametersType definition............................................... 23

Table 22 – NonSafetyDataPlaceholderDataType structure........................................... 27

Table 38 – Examples for cryptographically strong random number generators.................. 72

Table 39 – The total residual error rate for the safety communication channel.................. 76

Table 42 – NamespaceMetadata Object for this document........................................... 81

Table B.1 – The CRC32 lookup table for 32-bit CRC signature calculations..................... 84

OPC Foundation

____________

UNIFIED ARCHITECTURE

Part 15: Safety

This specification is the specification for developers of OPC UA applications. The specification is a result of an analysis and design process to develop a standard interface to facilitate the development of applications by multiple vendors that shall inter-operate seamlessly together.

Copyright © 2006-2024, OPC Foundation, Inc.

ACKNOWLEDGEMENT

This specification has its origin in a joint working group between the OPC Foundation and the PROFIBUS Nutzerorganisation e.V. (PNO) which was established in November 2017. The experts of this joint working group initially elaborated a safety concept for controller-to-controller communication using an approach according to IEC 61784-3 “Functional safety fieldbuses” based on the OPC UA Client/Server communication model. The launch of the Field Level Communication Initiative in November 2018 has resulted in an extension of the safety concept to also support controller-to-device communication and the Pub/Sub communication including transport via Ethernet and Ethernet TSN.

AGREEMENT OF USE

COPYRIGHT RESTRICTIONS

Any unauthorized use of this specification may violate copyright laws, trademark laws, and communications regulations and statutes. This document contains information which is protected by copyright. All Rights Reserved. No part of this work covered by copyright herein may be reproduced or used in any form or by any means--graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems--without permission of the copyright owner.

OPC Foundation members and non-members are prohibited from copying and redistributing this specification. All copies must be obtained on an individual basis, directly from the OPC Foundation Web site http://www.opcfoundation.org..

PATENTS

The attention of adopters is directed to the possibility that compliance with or adoption of OPC specifications may require use of an invention covered by patent rights. OPC shall not be responsible for identifying patents for which a license may be required by any OPC specification, or for conducting legal inquiries into the legal validity or scope of those patents that are brought to its attention. OPC specifications are prospective and advisory only. Prospective users are responsible for protecting themselves against liability for infringement of patents.

WARRANTY AND LIABILITY DISCLAIMERS

WHILE THIS PUBLICATION IS BELIEVED TO BE ACCURATE, IT IS PROVIDED “AS IS” AND MAY CONTAIN ERRORS OR MISPRINTS. THE OPC FOUDATION MAKES NO WARRANTY OF ANY KIND, EXPRESSED OR IMPLIED, WITH REGARD TO THIS PUBLICATION, INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF TITLE OR OWNERSHIP, IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE. IN NO EVENT SHALL THE OPC FOUNDATION BE LIABLE FOR ERRORS CONTAINED HEREIN OR FOR DIRECT, INDIRECT, INCIDENTAL, SPECIAL, CONSEQUENTIAL, RELIANCE OR COVER DAMAGES, INCLUDING LOSS OF PROFITS, REVENUE, DATA OR USE, INCURRED BY ANY USER OR ANY THIRD PARTY IN CONNECTION WITH THE FURNISHING, PERFORMANCE, OR USE OF THIS MATERIAL, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

The entire risk as to the quality and performance of software developed using this specification is borne by you.

RESTRICTED RIGHTS LEGEND

This Specification is provided with Restricted Rights. Use, duplication or disclosure by the U.S. government is subject to restrictions as set forth in (a) this Agreement pursuant to DFARs 227.7202-3(a); (b) subparagraph (c)(1)(i) of the Rights in Technical Data and Computer Software clause at DFARs 252.227-7013; or (c) the Commercial Computer Software Restricted Rights clause at FAR 52.227-19 subdivision (c)(1) and (2), as applicable. Contractor / manufacturer are the OPC Foundation, 16101 N. 82nd Street, Suite 3B, Scottsdale, AZ, 85260-1830.

COMPLIANCE

The OPC Foundation shall at all times be the sole entity that may authorize developers, suppliers and sellers of hardware and software to use certification marks, trademarks or other special designations to indicate compliance with these materials. Products developed using this specification may claim compliance or conformance with this specification if and only if the software satisfactorily meets the certification requirements set by the OPC Foundation. Products that do not meet these requirements may claim only that the product was based on this specification and must not claim compliance or conformance with this specification.

Trademarks

Most computer and software brand names have trademarks or registered trademarks. The individual trademarks have not been listed here.

GENERAL PROVISIONS

Should any provision of this Agreement be held to be void, invalid, unenforceable or illegal by a court, the validity and enforceability of the other provisions shall not be affected thereby.

This Agreement shall be governed by and construed under the laws of the State of Minnesota, excluding its choice or law rules.

This Agreement embodies the entire understanding between the parties with respect to, and supersedes any prior understanding or agreement (oral or written) relating to, this specification.

ISSUE REPORTING

The OPC Foundation strives to maintain the highest quality standards for its published specifications; hence they undergo constant review and refinement. Readers are encouraged to report any issues and view any existing errata here: http://www.opcfoundation.org/errata.

Revision 1.05.04 Highlights

The following table includes the issues resolved with this revision.

|

Mantis ID |

Scope |

Summary |

Resolution |

|

Errata |

Missing Documentation About Duration of Demand |

Added new Subclause 7.2.2.3 “Duration of demand“. Removed obsolete item 7 from Table 40. |

|

|

Clarification |

Clarify Byte Order of SafetyBaseID in Calculation of the SPDU_ID |

Added new Subclause 7.2.3.3 “Example for the calculation of SPDU_ID_1, SPDU_ID_2 and SPDU_ID_3 (informative)“. Adapted Figure 21 wording to IEC “octet(s)”. |

|

|

Clarification |

Merge Changes from IEC Standardization Document Stream |

Minor technical rewordings and editorial changes were backported from the IEC CD stage. |

|

|

Errata |

Misleading Wording in Requirement RQ7.15 About Order of Constructing ResponseSPDU |

In RQ7.15, replaced “after that“ with “in addition”. |

|

|

Clarification |

Requirement 5.6 "Ignore All-Zero SPDUs" Needs Detailing |

Detailing of requirement RQ5.6 regarding actual Client/Server behavior. |

|

|

Clarification |

Section about "Duration of Demand" misses explanations about timeout-based and bidirectional approaches |

Add respective explanations to 7.2.2.3. |

|

|

Errata |

Nodeset changes concerning missing HasComponent relations |

Added HasComponent relations to SafetyPDUs Objects’ RequestSPDU and ResponseSPDU. |

|

|

Errata |

Editorial Issues in 1.05.04 RC |

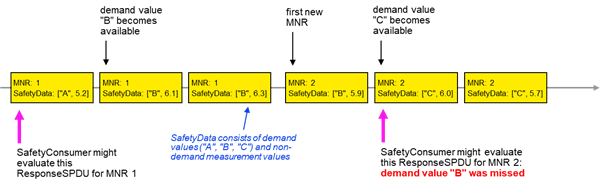

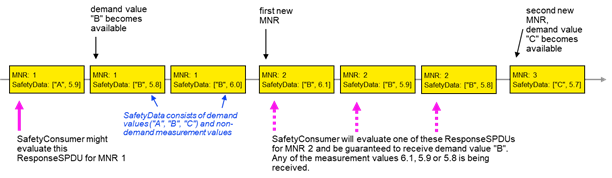

Removed unexplained bold red highlighting of method arguments OutSafetyData and OutNonSafetyData in signature descriptions for methods ReadSafetyData and ReadSafetyDiagnostics and added explanations that these are abstract types that have to be concretized for specific applications. Table 23: added missing blank after "document" in entry for SafetyConsumerID. Figure 9: corrected misalignment of SafetyConsumer in F-PLC. Table 24 – SPI of the SafetyProvider: adapted to consistent usage of range "0x0 – 0xFFFFFFFF" (vs. "0 – 0xFFFFFFFF"). Table 25 – SAPI of the SafetyConsumer: uniformly formatted terms in first column in italics. Table 26 – SPI of the SafetyConsumer: Harmonized the wording explaining the SafetyProviderIDConfigured parameter (using the wording from the SafetyBaseIDConfigured parameter). 6.3.4.3 - Motivation for SAPI Operator Acknowledge (OperatorAckConsumer): added link to 6.3.4.5 - Motivation for SPI SafetyOperatorAckNecessary to last paragraph. Figure 16: noted availability of demand value "C" at occurrence of second new MNR. |

OPC UA Safety extends OPC UA to fulfill the requirements of functional safety as defined in the IEC 61508 series and IEC 61784-3 series of standards.

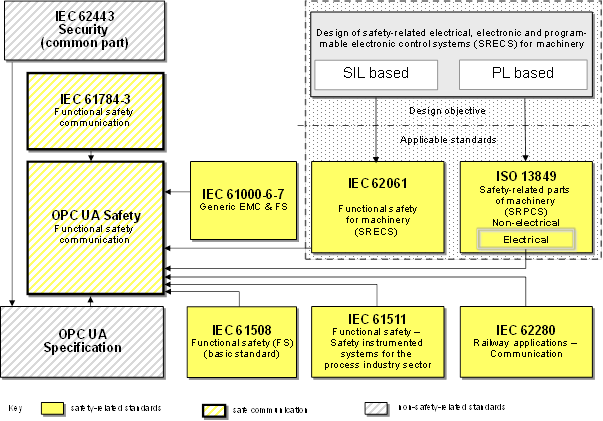

Figure 1 shows the relationship between this document and the relevant safety and OPC UA standards in an industrial environment. An arrow from Document A to Document B means “Document A is referenced in Document B”. This reference can be either normative or informative. Not all of these standards are applicable or required for a given product.

Figure 1 (informative) – Relationships of OPC UA Safety with other standards

Implementing this document allows for detecting all types of communication errors encountered in the lower network layers. In case an error is detected, this information is shared with the safety applications in the User Layer which can then act in an appropriate way, e.g. by switching to a safe state.

The document describes the behaviour of the individual endpoints for safe communication, as well as the OPC UA Information Model which is used to access these endpoints.

This document is application-independent and does not pose requirements on the structure and length of the application data. Application-specific requirements are expected to be described in appropriate companion specifications.

This document can be used for applications requiring functional safety up to the safety integrity level (SIL) 4.

OPC Unified Architecture Specification

Part 15: Safety

This document describes a safety communication layer (services and a protocol) for the exchange of SafetyData using OPC UA mechanisms. It identifies the principles for functional safety communications defined in IEC 61784‑3 that are relevant for this safety communication layer. This safety communication layer is intended for implementation in safety devices only.

NOTE 1 This document targets controller-to-controller communication. However, easy expandability to other use-cases (e.g. OPC UA field level communication) has already been considered in the design of this document.

NOTE 2 This document does not cover electrical safety and intrinsic safety aspects. Electrical safety relates to hazards such as electrical shock. Intrinsic safety relates to hazards associated with potentially explosive atmospheres.

This document defines mechanisms for the transmission of safety-relevant messages among participants within a network using OPC UA technology in accordance with the requirements of the IEC 61508 series and IEC 61784-3 for functional safety. These mechanisms can be used in various industrial applications such as process control, manufacturing, automation, and machinery.

This document provides guidelines for both developers and assessors of compliant devices and systems.

NOTE 3 The resulting SIL claim of a system depends on the implementation of this document within the system – implementation of this document in a standard device is not sufficient to qualify it as a safety device.

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

IEC 61508 (all parts), Functional safety of electrical/electronic/programmable electronic safety-related systems

IEC 61784‑3:2021, Industrial communication networks – Profiles – Part 3: Functional safety fieldbuses – General rules and profile definitions

IEC 62443 (all parts), Industrial communication networks – Network and system security

OPC 10000-1, OPC Unified Architecture – Part 1: Overview and Concepts

OPC 10000-3, OPC Unified Architecture – Part 3: Address Space Model

OPC 10000-4, OPC Unified Architecture – Part 4: Services

OPC 10000-5, OPC Unified Architecture – Part 5: Information Model

OPC 10000-6, OPC Unified Architecture – Part 6: Mappings

OPC 10000-14, OPC Unified Architecture – Part 14: PubSub

ISO/IEC 9834-8:2014, Information technology – Procedures for the operation of object identifier registration authorities – Part 8: Generation of universally unique identifiers (UUIDs) and their use in object identifiers

For the purposes of this document, the terms and definitions given in OPC 10000-1, OPC 10000-3, OPC 10000‑4, OPC 10000-6 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

· IEC Electropedia: available at https://www.electropedia.org/

· ISO Online browsing platform: available at https://www.iso.org/obp

NOTE This document uses concepts of OPC UA information modeling to describe the concepts in this document.

3.1.1.1

Cyclic Redundancy Check

CRC

<value> redundant data derived from, and stored or transmitted together with, a block of data in order to detect data corruption

<method> procedure used to calculate the redundant data

Note 1 to entry: Terms “CRC code” and “CRC signature”, and labels such as CRC1, CRC2, may also be used in this document to refer to the redundant data.

[SOURCE: IEC 61784-3:2021, 3.10]

3.1.1.2

error

discrepancy between a computed, observed or measured value or condition and the true, specified or theoretically correct value or condition

Note 1 to entry: Errors may be due to design mistakes within hardware/software and/or corrupted information due to electromagnetic interference and/or other effects.

Note 2 to entry: Errors do not necessarily result in a failure or a fault.

[SOURCE: IEC 60050-192:2024, 192-03-02, modified – notes added]

3.1.1.3

failure

termination of the ability of a functional unit to perform a required function or operation of a functional unit in any way other than as required

Note 1 to entry: Failure may be due to an error (for example, problem with hardware/software design or message disruption).

[SOURCE: IEC 61508‑4:2010, 3.6.4, modified – notes and figures deleted, new note to entry added]

3.1.1.4

fault

abnormal condition that may cause a reduction in, or loss of, the capability of a functional unit to perform a required function

Note 1 to entry: IEV 191‑05‑01 defines “fault” as a state characterized by the inability to perform a required function, excluding the inability during preventive maintenance or other planned actions, or due to lack of external resources.

[SOURCE: IEC 61508‑4:2010, 3.6.1, modified – figure reference deleted]

message

<information theory and communication theory> ordered sequence of characters (usually octets) intended to convey information

[SOURCE: ISO/IEC 2382:2015, 2123031, modified – insertion of "(usually octets)", deletion of notes and source]

3.1.1.6

performance level

PL

discrete level used to specify the ability of safety-related parts of control systems to perform a safety function under foreseeable conditions

[SOURCE: ISO 13849‑1:2023, 3.1.5]

3.1.1.7

residual error probability

probability of an error undetected by the SCL safety measures

[SOURCE: IEC 61784-3:2021 3.1]

3.1.1.8

residual error rate

statistical rate at which the SCL safety measures fail to detect errors

[SOURCE: IEC 61784-3:2021, 3.1.35]

3.1.1.9

safety communication layer

SCL

communication layer above the OPC UA communication stack that includes all necessary additional measures to ensure safe transmission of data in accordance with the requirements of IEC 61508

Note 1 to entry: The SCL provides several services, the most important ones being the SafetyProvider and the SafetyConsumer.

[SOURCE: IEC 61784-3:2021, 3.1.39 modified – “FAL” replaced by “OPC UA communication stack”, not to entry added]

safety function response time

worst case elapsed time following an actuation of a safety sensor connected to a fieldbus, until the corresponding safe state of its safety actuator(s) is achieved in the presence of errors or failures in the safety function

Note 1 to entry: This concept is introduced in IEC 61784‑3:2021, 5.2.4 and is addressed by the functional safety communication profiles defined in the IEC 61784-3 series of documents.

[SOURCE: IEC 61784-3:2021, 3.1.44]

3.1.1.11

safety integrity level

SIL

discrete level (one out of a possible four), corresponding to a range of safety integrity values, where safety integrity level 4 has the highest level of safety integrity and safety integrity level1 has the lowest

Note 1 to entry: The target failure measures (see IEC 61508‑4:2010, 3.5.17) for the four safety integrity levels are specified in Table 2 and Table 3 of IEC 61508‑1:2010.

Note 2 to entry: Safety integrity levels are used for specifying the safety integrity requirements of the safety functions to be allocated to the E/E/PE safety-related systems.

Note 3 to entry: A safety integrity level (SIL) is not a property of a system, subsystem, element or component. The correct interpretation of the phrase “SIL n safety-related system” (where n is 1, 2, 3 or 4) is that the system is potentially capable of supporting safety functions with a safety integrity level up to n.

[SOURCE: IEC 61508‑4:2010, 3.5.8]

3.1.1.12

safety measure

measure to control possible communication errors that is designed and implemented in compliance with the requirements of IEC 61508

Note 1 to entry: In practice, several safety measures are combined to achieve the required safety integrity level.

Note 2 to entry: Communication errors and related safety measures are detailed in IEC 61784‑3:2021, 5.3 and 5.4.

[SOURCE: IEC 61784-3:2021, 3.1.46]

safety PDU

SPDU

PDU transferred through the safety communication channel

Note 1 to entry: The SPDU may include more than one copy of the SafetyData using differing coding structures and hash functions together with explicit parts of additional protections such as a key, a sequence count, or a time stamp mechanism.

Note 2 to entry: Redundant SCLs may provide two different versions of the SPDU for insertion into separate fields of the OPC UA frame.

[SOURCE: IEC 61784-3:2021, 3.1.47]

3.1.2.1

fail-safe

ability of a system that, by adequate technical or organizational measures, prevents from hazards either deterministically or by reducing the risk to a tolerable measure

Note 1 to entry: Equivalent to functional safety.

3.1.2.2

fail-safe substitute values

FSV

values which are issued or delivered instead of process values when the safety function is set to a fail-safe state

Note 1 to entry: In this document, the fail-safe substitute values (FSV) are always set to binary “0”.

3.1.2.3

flag

one-bit value used to indicate a certain status or control information

3.1.2.4

Globally Unique Identifier

GUID

128-bit number used to identify information in computer systems

Note 1 to entry: The term universally unique identifier (UUID) is also used.

Note 2 to entry: In this document, UUID version 4 is used.

3.1.2.5

MonitoringNumber

MNR

means used to ensure the correct order among transmitted safety PDUs and to monitor the communication delay

Note 1 to entry: Instance of sequence number as described in IEC 61784‑3.

Note 2 to entry: The MNR starts at a random value and is incremented with each request. It rolls over to a minimum threshold value that is not zero.

Note 3 to entry: The transmitted MNR is protected by the transmitted CRC signature of the ResponseSPDU.

3.1.2.6

Non-safety-

predicate meaning that the respective object is a “standard” object and has not been designed and implemented to fulfil any requirements with respect to functional safety

3.1.2.7

OPC UA Mapper

non-safety-related part of the implementation of this document which maps the SPDU to the actual OPC UA services

Note 1 to entry: Depending on which services of OPC UA are being used (e.g. Client/Server or PubSub), different mappers can be specified.

3.1.2.8

process values

PV

input and output data (in a safety PDU) that are required to control an automated process

3.1.2.9

qualifier

attribute (bit or Boolean), indicating whether the corresponding value is valid or not (e.g. being a fail-safe substitute value)

3.1.2.10

SafetyAutomationComponent

SafetyAC

communication partner in a unidirectional safety link

Note 1 to entry: A SafetyAutomationComponent can be a SafetyProvider (data source), a SafetyConsumer (data sink), or both.

3.1.2.11

SafetyConsumer

entity (usually software) that implements the data sink of a unidirectional safety link

SafetyData

application data transmitted across a safety network using a safety protocol

Note 1 to entry; The safety communication layer does not ensure the safety of the data itself, but only that the data is transmitted safely.

3.1.2.13

SafetyProvider

entity (usually software) that implements the data source of a unidirectional safety link

SafetyBaseID

randomly generated authenticity ID which is used to safely authenticate SafetyProviders having the same SafetyProviderID

Note 1 to entry: Together with the SafetyProviderID, it is an instance of connection authentication as described in IEC 61784‑3.

SafetyProviderID

user-assigned, locally unique identifier which is used to safely authenticate SafetyProviders within a certain area

Note 1 to entry: Together with the SafetyBaseID, it is an instance of connection authentication as described in IEC 61784‑3.

Note 1 to entry: All SafetyProviders within an area such defined may share an identical SafetyBaseID.

3.1.2.16

standard transmission system

part of the transmission system (implemented in hardware and software) that is not implemented according to any safety standards

Note 1 to entry: This document is using the services of the standard transmission system to transmit prebuilt safety packets.

For the purposes of this document, the following symbols and abbreviated terms apply.

|

Cyclic Redundancy Check |

|

|

|

PDU |

Protocol Data Unit |

[ISO/IEC 7498‑1] |

|

PL |

Performance Level |

[ISO 13849‑1] |

|

PLC |

Programmable Logic Controller |

|

|

SCL |

Safety Communication Layer |

|

|

SIL |

safety integrity level |

[IEC 61508‑4] |

|

SPDU |

Safety PDU, Safety Protocol Data Unit |

|

|

Fail-safe substitute Values |

|

|

|

HMI |

Human-machine interface |

|

|

ID |

Identifier |

|

|

LSB |

Least significant bit |

|

|

MNR |

MonitoringNumber |

|

|

MSB |

Most significant bit |

|

|

OA |

Operator Acknowledgment |

|

|

OPC UA PI |

OPC UA Platform Interface |

|

|

PI |

Platform Interface |

|

|

PV |

Process Values |

|

|

SAPI |

Safety Application Program Interface |

|

|

SFRT |

Safety Function Response Time |

|

|

SPI |

Safety Parameter Interface |

|

|

STrailer |

Safety Trailer |

|

|

TRA |

threat and risk analysis |

|

|

p |

Bit error probability |

|

|

Pre,cond |

Conditional residual error probability |

|

Italics are used to denote a defined term or definition that appears in 3.1.

Italics are also used to denote the name of a service input or output parameter or the name of a structure or element of a structure that are usually defined in tables.

The italicized terms and names are also often written in camel-case (the practice of writing compound words or phrases in which the elements are joined without spaces, with each element's initial letter capitalized within the compound). For example, the defined term is AddressSpace instead of Address Space. This makes it easier to understand that there is a single definition for AddressSpace, not separate definitions for Address and Space. Terms or names where two capital letters of abbreviations are in sequence or for separation to a suffix are written with underscores in between.

The abbreviation “F” is an indication for safety- related items, technologies, systems, and units (fail-safe, functional safe).

The default data that are used in case of unit failures or errors, are called fail-safe substitute values (FSV) and are set to binary “0”.

Reserved bits (“res”) are set to “0” and ignored by the receiver to avoid problems with future versions of this document.

The notation 0x… represents a hexadecimal value.

Requirements in this document are designated as [RQx.yz], where x denotes the chapter number, y is a counter and z is an optional character to link closely related requirements. The following are examples of valid requirements designations: [RQ8.15] (requirement 15 in chapter 8); [RQ47.11a], [RQ47.11b] (requirements 11a and 11b in chapter 47, which are closely related).

The initial numbering of requirements was chosen such that counters within each chapter are in ascending order. However, the addition of further requirements leads to deviations from this rule since existing requirements shall keep their initial designation.

For an informative index of all the requirements in this document, see 10.3.

See Table 1 for the conventions used in state machines.

Table 1 – Conventions used in state machines

|

Convention |

Meaning |

|

:= |

Assignment: value of an item on the left is replaced by value of the item on the right. |

|

< |

Less than: a logical condition yielding TRUE if and only if an item on the left is less than the item on the right. |

|

<= |

Less or equal than: a logical condition yielding TRUE if and only if an item on the left is less or equal than the item on the right. |

|

> |

Greater than: a logical condition yielding TRUE if and only if the item on the left is greater than the item on the right. |

|

>= |

Greater or equal than: a logical condition yielding TRUE if and only if the item on the left is greater or equal than the item on the right. |

|

== |

Equality: a logical condition yielding TRUE if and only if the item on the left is equal to an item on the right. |

|

<> |

Inequality: a logical condition yielding TRUE if and only if the item on the left is not equal to an item on the right. |

|

&& |

Logical “AND” (Operation on binary values or results). |

|

|| |

Logical “OR” (Operation on binary values or results). |

|

|

Logical “XOR” (Operation on binary values or digital values). |

|

[..] |

UML Guard condition, if and only if the guard is TRUE the respective transition is enabled. |

This document specifies a safety communication layer (SCL) allowing safety-related devices to use the services of OPC UA for the safe exchange of safety-related data. A safety device that implements OPC UA Safety correctly will be able to exchange safety-related data and hereby fulfill the requirements of the IEC 61508 series and IEC 61784-3. This document uses a MonitoringNumber, a timeout, a set of IDs and a cyclic redundancy check (CRC)code for the detection of all possible communication errors which can happen in the underlying OPC UA standard transmission system. These safety measures have been quantitatively evaluated and offer a probability of dangerous failure per hour (PFH) and a probability of dangerous failure on demand (PFD) sufficing to build safety-related applications with a safety integrity level of up to SIL4.

OPC UA Safety itself is an application-independent, general solution. The length and structure of the data sent is defined by the safety application. However, application-dependent companion specifications (addressing for example electro-sensitive protective equipment, electric drives with safety functions, forming presses, robot safety, and automated guided vehicles) are expected to be defined by application-experts in appropriate OPC UA companion specifications.

[RQ4.1] All technical measures for error detection described in this document shall be implemented within the SCL in devices designed in accordance with the IEC 61508 series and shall meet the target SIL.

· Runs on top of:

– OPC UA Client/Server with the Method Service Set.

– OPC UA PubSub.

· From an architectural point of view: easy extensibility for other ways of communication.

· goal: no modification of existing OPC UA framework.

· The state machines of this document are independent from the OPC UA Mapper, allowing for a simplified exchange of the mapper.

· Ready for wireless transmission channels.

· Modest requirements on safety network nodes:

– No clock synchronization is necessary (no requirements regarding the accuracy between clocks at different nodes).

– Within the SafetyConsumer, a safety-related, local timer is required for implementing the SafetyConsumerTimeout. The accuracy of this timer depends on the timing requirements of the safety application.

· End-to-End Safety: functional SafetyData is transported between two safety endpoint devices across a standard network that is not functionally safety compliant. This includes the lower transport layers such as the OPC UA stack, underlying physical media, and non-safety network elements (e.g. routers and switches).

· “Dynamic” systems:

– Safety communication partners can change during runtime,

– either an increase or decrease, or both, in the number of safety communication partners can occur.

· Well-defined text-strings are used for diagnostic purposes.

· Safety communication and standard communication are independent. However, standard devices and safety devices can use the same standard transmission system at the same time.

· Functional safety can be achieved without using structurally redundant standard transmission systems i.e. a single channel approach can be used. Redundancy can be used optionally for increased availability.

· For diagnostic purposes, the last SPDU sent and received is accessible in the Information Model of the SafetyProvider.

· Length of user data: 1 octet to 1 500 octets, structures of basic DataTypes, see 6.2.5.

In the final application, an appropriate security environment is necessary to protect both the operational environment and the safety-related systems.

This document does not cover security aspects, nor does it provide any requirements for security.

A threat and risk analysis (TRA) according to the IEC 62443 series shall be carried out on a final application system level.

During compliance tests for this document, security aspects are not part of the scope, as it is assumed that the underlying base mechanisms (i.e. Methods) already provide adequate security.

No other external documents are providing specifications in addition to the Normative references given in Clause 2.

The following requirements apply for the development of this document:

a) Safety communication suitable for safety integrity level up to SIL4 (see the IEC 61508 series) and PL e (see ISO 13849‑1).

b) Combination of SIL 1 to 4 devices according to this document as well as non-safety devices on one communication network.

c) Implementation of the safety transmission protocol is restricted to the safety layer.

d) The safety-relevant time-out monitoring is implemented in the safety layer.

e) Safety communication meet the requirements of IEC 61784‑3.

f) [RQ5.1] This document is intended for implementation in safety devices exclusively. Exceptions (e.g. for debugging, simulation, testing, and commissioning) shall be discussed with a notified body.

[RQ5.2] For an implementation of this document, the following safety measures shall be implemented: MonitoringNumber; timeout with receipt in the SafetyConsumer; set of IDs for the SafetyProvider; Data Integrity check.

Together, these safety measures address all possible transmission errors as listed in IEC 61784‑3:2021, 5.5, see Table 2.

[RQ5.3] The safety measures shall be processed and monitored within the SCL.

Table 2 – Deployed safety measures to detect communication errors

|

Communication error |

Safety measures |

|||

|

MonitoringNumber a |

Timeout with receipt b |

Set of IDs for SafetyProvider c |

Data

integrity |

|

|

Corruption |

– |

– |

– |

X |

|

Unintended repetition |

X |

X |

– |

– |

|

Incorrect sequence |

X |

– |

– |

– |

|

Loss |

X |

X |

– |

– |

|

Unacceptable delay |

– |

X |

– |

– |

|

Insertion |

X |

– |

– |

– |

|

Masquerade |

X |

– |

X |

X |

|

Addressing |

– |

– |

X |

– |

|

a Instance of “sequence number” of IEC 61784‑3. b Instance of “time expectation” (timeout) and “feedback message” (receipt) of IEC 61784‑3. c Instance of “connection authentication” of IEC 61784‑3. d Instance of “data integrity assurance” of IEC 61784‑3, based on CRC signature. |

||||

The SafetyConsumer is specified in such a way that for any communication error according to Table 2, a defined fault reaction will occur.

In all cases, the faulty SPDU will be discarded, and not forwarded to the safety application.

Moreover, if the error rate is too high, the SafetyConsumer is defined in such a way that it will cease to deliver actual process values to the safety application but will deliver fail-safe substitute values instead. In addition, an indication at the Safety Application Program Interface is set which can be queried by the safety application.

In case the error rate is still considered acceptable, the state machine repeats the request, see 9.4.

This document is based on:

· the standard transmission system according to OPC UA

· an additional safety transmission protocol on top of this standard transmission system

Safety applications and standard applications share the same standard OPC UA communication systems at the same time. The safe transmission function incorporates safety measures to detect faults or hazards that originate in the standard transmission system which have a potential to compromise the safety subsystems. This includes faults such as:

· Random errors, for example due to electromagnetic interference on the transmission channel;

· Failures or faults of the standard hardware;

· Systematic malfunctions of components within the standard hardware and software.

This principle delimits the assessment effort to the “safe transmission functions”. The standard transmission system does not require any additional functional safety assessment.

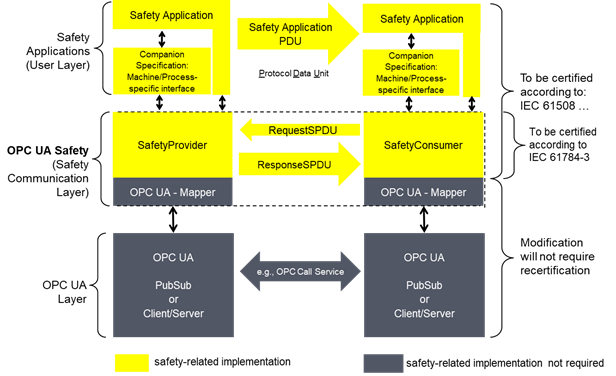

The basic communication layers of this document are shown in Figure 2.

Figure 2 – Safety layer architecture

Summary of the architecture:

Part: User Layer

The safety applications in the User Layer are either directly connected to the SafetyProvider or SafetyConsumer, or they are connected via a machine-specific or process-specific interface, which is described in companion specifications (e.g. sectoral).

The safety applications are expected to be designed and implemented according to the IEC 61508 series.

The Safety applications in the User Layer are not within the scope of this document.

Part: OPC UA Safety (Safety Communication Layer)

This layer is within the scope of this document. It defines the two services SafetyProvider and SafetyConsumer as basic building blocks. Together, they form the safety communication layer (SCL), implemented in a safety-related way according to the IEC 61508 series.

SafetyData is transmitted using point-to-point communication (unidirectional). Each unidirectional data flow internally communicates in both directions, using a requestand response pattern. This allows for checking the timeliness of messages using a single clock in the SafetyConsumer, thus eliminating the necessity for synchronized clocks.

When SafetyConsumers connect to SafetyProviders, they have prior expectations regarding the pair of SafetyProviderID and SafetyBaseID (e.g. by configuration). If this expectation is not fulfilled by the SafetyProvider, fail-safe substitute values are delivered to the safety application instead of the received process values. In contrast, it is not necessary for a SafetyProvider to know the SafetyConsumerID of the SafetyConsumer and will provide its process values to any SafetyConsumer requesting it.

SafetyProviders can not detect communication errors. All required error detection is performed by the SafetyConsumer.

If it is necessary for a pair of safety applications to exchange SafetyData in both directions, two pairs of SafetyProviders and SafetyConsumers shall be established, one pair for each direction.

The OPC UA Mapper implements the parts of the safety communication layer which are specific for the OPC UA communication Service in use, i.e. PubSub or Client/Server. Therefore, the remaining parts of the safety communication layer can be implemented independent of the OPC UA Service being used.

Part: OPC UA Layer

Client/Server:

· The SafetyProvider is implemented using an OPC UA Server providing a Method.

· The SafetyConsumer is implemented using an OPC UA Client calling the Method provided by the SafetyProvider.

PubSub:

· The SafetyProvider publishes the ResponseSPDU and subscribes to the RequestSPDU.

· The SafetyConsumer publishes the RequestSPDU and subscribes to the ResponseSPDU.

[RQ5.4] Any CRC signature calculation shall start with a preset value of “1”.

[RQ5.5] Any CRC signature calculation resulting in a “0” value, shall use the value “1” instead.

[RQ5.6] SPDUs with all values (incl. CRC signature) being zero shall be ignored by the receiver (SafetyConsumer and SafetyProvider). For Client/Server communication, this means that a Method Call with all fields making up the RequestSPDU being zero shall be answered with all fields making up the ResponseSPDU being zero. Neither of these SPDUs shall be presented to the respective state machines.

Clause 6 describes the integration of this document into the OPC UA Information Models in 6.2 and the resulting Service interfaces in 6.3. Diagnostic services are described in 6.4.

Subclause 6.2 describes the identifiers, types and structure of the Objects and Methods that are used to implement the OPC UA mappers defined in this document. This implementation serves three purposes:

· support of the safe exchange of SPDUs at runtime

· online browsing, to identify SafetyConsumers and SafetyProviders, and to check their parameters for diagnostic purposes

· offline engineering: the Information Model of one controller can be exported in a standardized file on its engineering system, be imported in another engineering system, and finally deployed on another controller. This allows for a vendor-independent exchange of the communication interfaces of safety applications, e.g. for establishing connections between devices.

NOTE Neither online browsing nor offline engineering currently supports any features to detect errors. Hence, no guarantees with respect to functional safety are made. This means that online browsing can only be used for diagnostic purposes, and not for exchanging safety-relevant data. It is assumed that errors can occur during the transfer of the Information Model from one engineering system to another in the context of offline engineering. Therefore, the programmer of the safety application is responsible for the verification and validation of the safety application.

Consequently, all type values described in 6.2 are defined as read-only, i.e. they cannot be written by general OPC UA write commands.

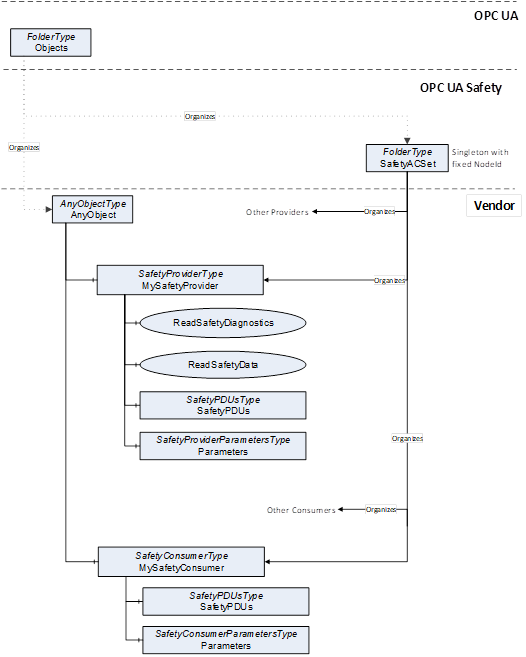

[RQ6.1] Each Server shall have a singleton Folder called SafetyACSet with a fixed NodeID in the Namespace of this document. Because all SafetyProviders and SafetyConsumers on this Server contain a hierarchical Reference from this Object to themselves, it can be used to directly access all SafetyProviders and SafetyConsumers. SafetyACSet is intended for safety-related purposes only. It should not reference non-safety-related items.

See Table 3 for the definition of the SafetyACSet.

Table 3 – SafetyACSet definition

|

Attribute |

Value |

||

|

BrowseName |

SafetyACSet |

||

|

References |

NodeClass |

BrowseName |

Comment |

|

OrganizedBy by the Objects Folder defined in OPC 10000-5. |

|||

|

HasTypeDefinition |

ObjectType |

FolderType |

Entry point for all SafetyProviders and SafetyConsumers |

|

Conformance Units |

|||

|

SafetyACSet |

|||

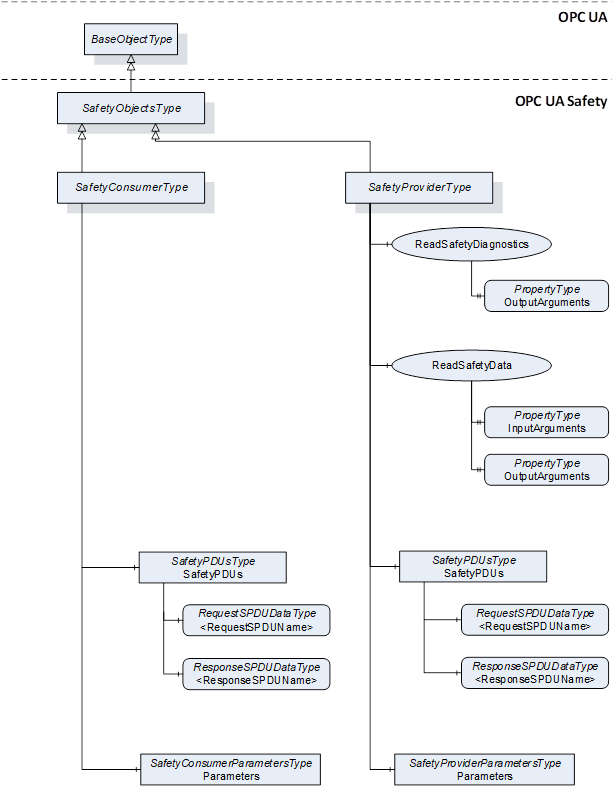

[RQ6.2] In addition, a Server shall comprise one OPC UA Object derived from DataType SafetyProviderType for each SafetyProvider it implements, and one OPC UA Object derived from DataType SafetyConsumerType for each SafetyConsumer it implements. The corresponding Information Models shown in Figure 3 and Figure 4 shall be used.

A description of the graphical notation for the different types of Nodes and References (shown in Figure 3, Figure 4, and Figure 6) can be found in OPC UA 10000-3.

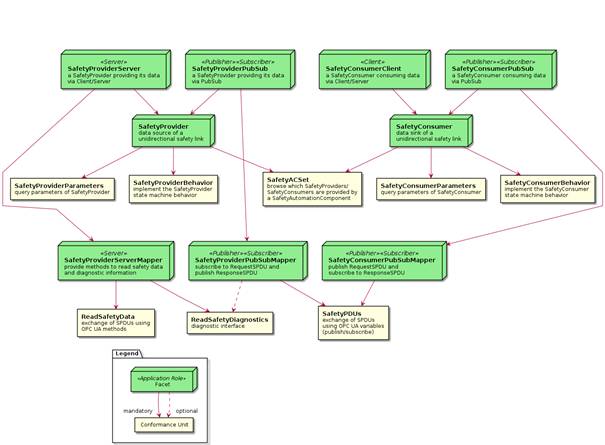

Figure 3 describes the SafetyProvider and the SafetyConsumer.

NOTE 1 This document assumes (atomic) consistent data exchange between OPC mappers of the two endpoints.

[RQ6.3a] For implementations supporting OPC UA Client/Server, the Call Service of the Method Service Set (see OPC UA 10000-4) shall be used. The Method ReadSafetyData has a set of input arguments that make up the RequestSPDU and a set of output arguments that make up the ResponseSPDU. The SafetyConsumer uses the OPC UA Client with the OPC UA Service Call.

[RQ6.3b] For implementations supporting OPC UA PubSub, the OPC UA Object SafetyPDUs with its Properties RequestSPDU and ResponseSPDU shall be used. RequestSPDU is published by the SafetyConsumer and subscribed by the SafetyProvider. ResponseSPDU is published by the SafetyProvider and subscribed by the SafetyConsumer.

NOTE 2 The terms “request” and “response” refer to the behaviour on the layer of this document. Within the PubSub context, both requests and responses are realized by repeatedly publishing and subscribing Messages, see Figure 14.

[RQ6.4] For diagnostic purposes, the SPDUs received and sent shall be accessible by calling the Method ReadSafetyDiagnostics.

Figure 3 – Server Objects for OPC UA Safety

NOTE 3 For the input/output arguments of the Methods ReadSafetyData and ReadSafetyDiagnostics, see 6.2.2.3 and 6.2.2.4. For the parameters of the SafetyProvider and SafetyConsumer, see Figure 6, Table 12, and Table 13. For RequestSPDU and ResponseSPDU, see Table 7, Table 18, Table 20, and 7.2.1.

Figure 4 shows the instances of Server Objects for this document. The ObjectType for the SafetyProviderType contains Methods having outputs of the abstract DataType Structure. Each instance of a SafetyProvider requires its own copy of the Methods which contain the concrete DataTypes for OutSafetyData and OutNonSafetyData.

Figure 4 – Instances of Server Objects for this document

[RQ6.5] To reduce the number of variations and to alleviate validation testing, the following restrictions apply to instances of SafetyProviderType and SafetyConsumerType (or instances of DataTypes derived from SafetyProviderType or SafetyConsumerType):

1) The references shown in Figure 4 originating at SafetyProviderType or SafetyConsumerType and below shall be of ReferenceType HasComponent (and shall not be derived from ReferenceType HasComponent) for Object References or ReferenceType HasProperty (and shall not be derived from ReferenceType HasProperty) for Property References.

2) As BrowseNames (i.e. name and Namespace) are used to find Methods, the names of Objects and Properties shall be locally unique.

3) The DataType of both Properties and MethodArguments shall be used as specified, and no derived DataTypes shall be used (exception: OutSafetyData and OutNonSafetyData).

4) In IEC 62541, the order of Method arguments is relevant.

See Table 4 for the definition of the SafetyObjectsType.

Table 4 – SafetyObjectsType definition

|

Attribute |

Value |

||||

|

BrowseName |

SafetyObjectsType |

||||

|

IsAbstract |

True |

||||

|

References |

Node class |

BrowseName |

DataType |

TypeDefinition |

Modelling rule |

|

Subtype of BaseObjectType |

|||||

|

Conformance units |

|||||

|

SafetySupport |

|||||

See Table 5 for the definition of the SafetyProviderType.

Table 5 – SafetyProviderType definition

|

Attribute |

Value |

||||

|

BrowseName |

SafetyProviderType |

||||

|

IsAbstract |

False |

||||

|

References |

Node class |

BrowseName |

DataType |

TypeDefinition |

Modelling rule |

|

Subtype of SafetyObjectsType |

|||||

|

HasComponent |

Method |

ReadSafetyData |

|

|

Optional |

|

HasComponent |

Method |

ReadSafetyDiagnostics |

|

|

Optional |

|

HasComponent |

Object |

SafetyPDUs |

|

SafetyPDUsType |

Optional |

|

HasComponent |

Object |

Parameters |

|

SafetyProviderParametersType |

Mandatory |

|

Conformance units |

|||||

|

SafetyProviderParameters |

|||||

[RQ6.6] Instances of SafetyProviderType shall use non-abstract DataTypes for the arguments OutSafetyData and OutNonSafetyData.

See Table 6 for the definition of the SafetyConsumerType.

Table 6 – SafetyConsumerType definition

|

Attribute |

Value |

||||

|

BrowseName |

SafetyConsumerType |

||||

|

IsAbstract |

False |

||||

|

References |

Node class |

BrowseName |

DataType |

TypeDefinition |

Modelling rule |

|

Subtype of SafetyObjectsType |

|||||

|

HasComponent |

Object |

SafetyPDUs |

|

SafetyPDUsType |

Optional |

|

HasComponent |

Object |

Parameters |

|

SafetyConsumerParametersType |

Mandatory |

|

Conformance units |

|||||

|

SafetyConsumerParameters |

|||||

This Method is mandatory for the Facet SafetyProviderServerMapper. It is used to read SafetyData from the SafetyProvider. It is in the responsibility of the safety application that this Method is not concurrently called by multiple SafetyConsumers. Otherwise, the SafetyConsumer can receive invalid responses resulting in a safe reaction which can lead to either spurious trips or system unavailability, or both.

See Table 7 for Method ReadSafetyData’s arguments and Table 8 for its AdressSpace definition.

The Method argument OutSafetyData has an application-specific DataType derived from Structure. This DateType (including the DataTypeID) is expected to be the same in both the SafetyProvider and the SafetyConsumer. Otherwise, the SafetyConsumer will not accept the transferred data and switch to fail-safe substitute values instead (see state S16 in Table 34 as well as 7.2.3.2 and 7.2.3.5). The Method argument OutNonSafetyData has an application-specific DataType derived from Structure.

Signature

ReadSafetyData (

[in] UInt32 InSafetyConsumerID,

[in] UInt32 InMonitoringNumber,

[in] InFlagsType InFlags,

[out] Structure OutSafetyData,

[out] OutFlagsType OutFlags,

[out] UInt32 OutSPDU_ID_1,

[out] UInt32 OutSPDU_ID_2,

[out] UInt32 OutSPDU_ID_3,

[out] UInt32 OutSafetyConsumerID,

[out] UInt32 OutMonitoringNumber,

[out] UInt32 OutCRC,

[out] Structure OutNonSafetyData)

;

Table 7 – ReadSafetyData Method arguments

|

Argument |

Description |

|

|

InSafetyConsumerID |

“Safety Consumer Identifier”, see SafetyConsumerID in Table 23. |

|

|

InMonitoringNumber |

“MonitoringNumber of the RequestSPDU”, see 7.2.1.3 and MonitoringNumber in Table 23. |

|

|

InFlags |

“Octet with non-safety-related flags from SafetyConsumer”, see 6.2.3.1. |

|

|

OutSafetyData |

“SafetyData”, see 7.2.1.5. |

|

|

OutFlags |

“Octet with safety-related flags from SafetyProvider”, see 6.2.3.2. |

|

|

OutSPDU_ID_1 |

“Safety PDU Identifier Part1”, see 7.2.3.2. |

|

|

OutSPDU_ID_2 |

“Safety PDU Identifier Part2”, see 7.2.3.2. |

|

|

OutSPDU_ID_3 |

“Safety PDU Identifier Part3”, see 7.2.3.2. |

|

|

OutSafetyConsumerID |

“Safety Consumer Identifier”, see SafetyConsumerID in Table 23 and Table 26. |

|

|

OutMonitoringNumber |

MonitoringNumber of the ResponseSPDU, see 7.2.1.9, 7.2.3.1, and Figure 11. |

|

|

OutCRC |

CRC over the ResponseSPDU, see 7.2.3.6. |

|

|

OutNonSafetyData |

“Non-safe data” see 7.2.1.11. |

|

Table 8 – ReadSafetyData Method AddressSpace definition

|

Attribute |

Value |

||||

|

BrowseName |

ReadSafetyData |

||||

|

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

ModellingRule |

|

HasProperty |

Variable |

InputArguments |

Argument[] |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

OutputArguments |

Argument[] |

PropertyType |

Mandatory |

|

Conformance units |

|||||

|

ReadSafetyData |

|||||

This Method is mandatory for the Facet SafetyProviderServerMapper and optional for the Facet SafetyProviderPubSubMapper. It is provided for each SafetyProvider serving as a Diagnostic Interface, see 6.4.3.

See Table 9 for the arguments of Method ReadSafetyDiagnostics and Table 10 for its AddressSpace definition.

The Method arguments OutSafetyData and OutNonSafetyData are application-specific types derived from Structure.

Signature

ReadSafetyDiagnostics (

[out] UInt32 InSafetyConsumerID,

[out] UInt32 InMonitoringNumber,

[out] InFlagsType InFlags,

[out] Structure OutSafetyData,

[out] OutFlagsType OutFlags,

[out] UInt32 OutSPDU_ID_1,

[out] UInt32 OutSPDU_ID_2,

[out] UInt32 OutSPDU_ID_3,

[out] UInt32 OutSafetyConsumerID,

[out] UInt32 OutMonitoringNumber,

[out] UInt32 OutCRC,

[out] Structure OutNonSafetyData)

;

Table 9 – ReadSafetyDiagnostics Method arguments

|

Argument |

Description |

|

|

InSafetyConsumerID |

see Table 7 |

|

|

InMonitoringNumber |

see Table 7 |

|

|

InFlags |

see Table 7 |

|

|

OutSafetyData |

see Table 7 |

|

|

OutFlags |

see Table 7 |

|

|

OutSPDU_ID_1 |

see Table 7 |

|

|

OutSPDU_ID_2 |

see Table 7 |

|

|

OutSPDU_ID_3 |

see Table 7 |

|

|

OutSafetyConsumerID |

see Table 7 |

|

|

OutMonitoringNumber |

see Table 7 |

|

|

OutCRC |

see Table 7 |

|

|

OutNonSafetyData |

see Table 7 |

|

Table 10 – ReadSafetyDiagnostics Method AddressSpace definition

|

Attribute |

Value |

||||

|

BrowseName |

ReadSafetyDiagnostics |

||||

|

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

ModellingRule |

|

HasProperty |

Variable |

OutputArguments |

Argument[] |

PropertyType |

Mandatory |

|

Conformance units |

|||||

|

ReadSafetyDiagnostics |

|||||

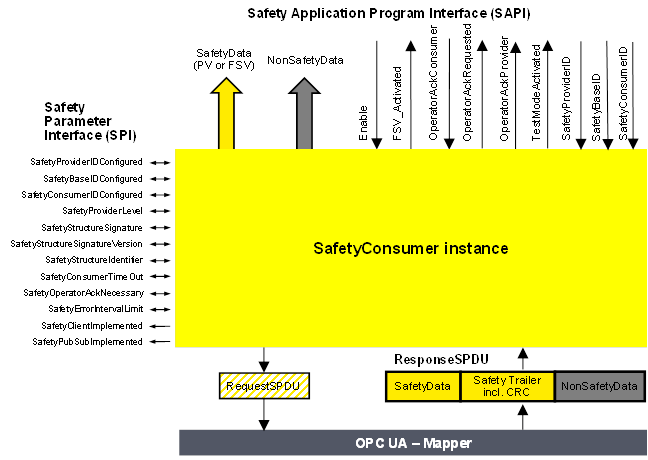

This Object is mandatory for the Facet SafetyProviderPubSubMapper and the Facet SafetyConsumerPubSubMapper It is used by the SafetyProvider to subscribe to the RequestSPDU and to publish the ResponseSPDU. The DataType of RequestSPDU is structured in the same way as the input arguments of ReadSafetyData. The DataType of ResponseSPDU is structured in the same way as the output arguments of ReadSafetyData.

See Table 11 for the definition of the SafetyPDUsType.

Both variables in the SafetyPDUsType have a counterpart within the Information Model of the SafetyConsumer. The SafetyConsumer publishes the RequestSPDU and subscribes to the ResponseSPDU.

Table 11 – SafetyPDUsType definition

|

Attribute |

Value |

|||||

|

BrowseName |

SafetyPDUsType |

|||||

|

IsAbstract |

False |

|||||

|

References |

Node class |

BrowseName |

DataType |

TypeDefinition |

Modelling rule |

|

|

Subtype of BaseObjectType |

||||||

|

HasComponent |

Variable |

<RequestSPDU> |

RequestSPDUDataType |

BaseDataVariableType |

Mandatory Placeholder |

|

|

HasComponent |

Variable |

<ResponseSPDU> |

ResponseSPDUDataType |

BaseDataVariableType |

Mandatory Placeholder |

|

|

Conformance units |

|

|||||

|

SafetyPDUs |

||||||

The Object SafetyPDUs shall contain exactly one Reference to a Variable of DataType RequestSPDUDataType and exactly one Reference to a Variable of a subtype of DataType ResponseSPDUDataType.

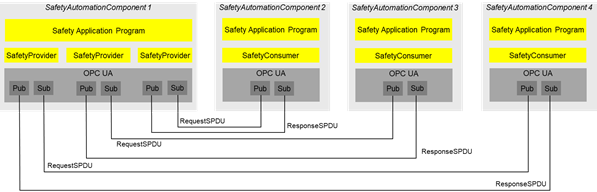

For example, Figure 5 shows a distributed safety application with four SafetyAutomationComponents. It is assumed that SafetyAutomationComponent 1 sends a value to the other three SafetyAutomationComponents using three SafetyProviders, each comprising a pair of SPDUs. For each recipient, there is an individual pair of SPDUs.

Figure 5 – Safety multicast with three recipients using IEC 62541 PubSub

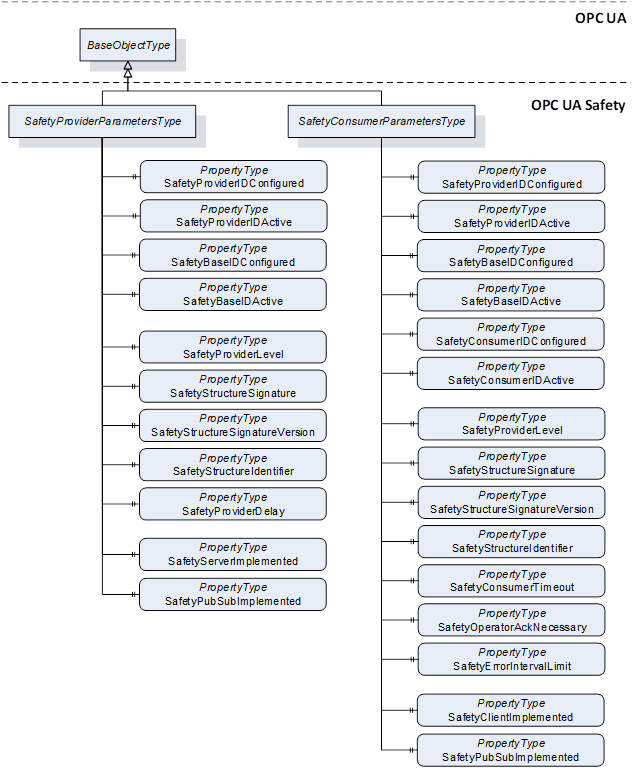

Figure 6 shows the safety parameters for the SafetyProvider and the SafetyConsumer.

Figure 6 – Safety parameters for the SafetyProvider and the SafetyConsumer

Table 12 shows the definition for the SafetyProviderParametersType. Refer to 6.3.3.3 for more details on the Safety Parameter Interface (SPI) of the SafetyProvider.

Table 12 – SafetyProviderParametersType definition

|

Attribute |

Value |

||||

|

BrowseName |

SafetyProviderParametersType |

||||

|

IsAbstract |

False |

||||

|

References |

Node class |

BrowseName |

DataType |

TypeDefinition |

Modelling rule |

|

Subtype of BaseObjectType |

|||||

|

HasProperty |

Variable |

SafetyProviderIDConfigured |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyProviderIDActive |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyBaseIDConfigured |

Guid |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyBaseIDActive |

Guid |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyProviderLevel |

Byte |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyStructureSignature |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyStructureSignatureVersion |

UInt16 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyStructureIdentifier |

String |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyProviderDelay |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyServerImplemented |

Boolean |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyPubSubImplemented |

Boolean |

PropertyType |

Mandatory |

|

Conformance units |

|||||

|

SafetyProviderParameters |

|||||

The parameters for SafetyProviderID and SafetyBaseID exist in pairs for “Configured” and “Active” states:

· SafetyProviderIDConfigured and SafetyProviderIDActive,

· SafetyBaseIDConfigured and SafetyBaseIDActive.

The “[...]Configured” parameters shall always deliver the values as configured via the SPI. The “[...]Active” parameters shall deliver:

· the corresponding “[...]Configured” values if the system is still offline;

· the values which have been set during runtime via the SAPI parameters (SafetyProviderID, SafetyBaseID);

· the corresponding “[...]Configured” values if the active values have been set to zero via the SAPI parameters (SafetyProviderID, SafetyBaseID).

The Property SafetyBaseIDConfigured is shared for all SafetyProviders with the same SafetyBaseIDConfigured value. If multiple instances of SafetyObjectsType are running on the same Node, it is a viable optimization that a Property SafetyBaseIDConfigured is referenced by either multiple SafetyProviders or SafetyConsumers, or both.

For releases up to Release 2.0 of the document, the value for the SafetyStructureSignatureVersion shall be 0x0001 (see RQ7.21 in 7.2.3.5).

Table 13 shows the definition of the SafetyConsumerParametersType. The Properties SafetyStructureIdentifier and SafetyStructureSignatureVersion are optional, because SafetyStructureSignature is typically calculated in an offline engineering tool. For small devices, it could be beneficial to only upload the SafetyStructureSignature to the device, but not SafetyStructureIdentifier and SafetyStructureSignatureVersion in order to save either bandwidth or memory, or both. Refer to 6.3.4.4 for more details on the Safety Parameter Interface (SPI) of the SafetyConsumer.

Table 13 – SafetyConsumerParametersType definition

|

Attribute |

Value |

||||

|

BrowseName |

SafetyConsumerParametersType |

||||

|

IsAbstract |

False |

||||

|

References |

Node class |

BrowseName |

DataType |

TypeDefinition |

Modelling rule |

|

Subtype of BaseObjectType |

|||||

|

HasProperty |

Variable |

SafetyProviderIDConfigured |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyProviderIDActive |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyBaseIDConfigured |

Guid |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyBaseIDActive |

Guid |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyConsumerIDConfigured |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyConsumerIDActive |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyProviderLevel |

Byte |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyStructureSignature |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyStructureSignatureVersion |

UInt16 |

PropertyType |

Optional |

|

HasProperty |

Variable |

SafetyStructureIdentifier |

String |

PropertyType |

Optional |

|

HasProperty |

Variable |

SafetyConsumerTimeout |

UInt32 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyOperatorAckNecessary |

Boolean |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyErrorIntervalLimit |

UInt16 |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyClientImplemented |

Boolean |

PropertyType |

Mandatory |

|

HasProperty |

Variable |

SafetyPubSubImplemented |

Boolean |

PropertyType |

Mandatory |

|

Conformance units |

|||||

|

SafetyConsumerParameters |

|||||

The parameters for SafetyProviderID, SafetyBaseID and SafetyConsumerID exist in pairs for “Configured” and “Active” states: SafetyProviderIDConfigured and SafetyProviderIDActive, SafetyBaseIDConfigured and SafetyBaseIDActive, and SafetyConsumerIDConfigured and SafetyConsumerIDActive.

The “[...]Configured” parameters shall always deliver the values as configured via the SPI. The “[...]Active” parameters shall deliver:

· the corresponding “[...]Configured” values if the system is still offline;

· the values which have been set during runtime via the SAPI parameters (SafetyProviderID, SafetyBaseID, SafetyConsumerID);

· the corresponding “[...]Configured” values if the active values have been set to zero via the SAPI parameters (SafetyProviderID, SafetyBaseID, SafetyConsumerID).

The InFlagsType a subtype of the Byte DataType with the OptionSetValues Property defined. The InFlagsType is formally defined in Table 14.

CommunicationError can be used as a trigger, e.g. for a communication analysis tool. It is not forwarded to the safety application by the SafetyProvider. If CommunicationError is necessary in the safety application, bidirectional communication can be implemented and the value of CommunicationError can be put into the user data.

Table 14 – InFlagsType values

|

Value |

Bit no. |

Description |

|

CommunicationError |

0 |

0: No error 1: An error was detected in the previous ResponseSPDU. |

|

OperatorAckRequested |

1 |

Used to inform the SafetyProvider that operator acknowledgment is requested. |

|

FSV_Activated |

2 |

Used for conformance test of SafetyConsumer.SAPI.FSV_Activated. |

Bits 3 to 7 are reserved for future use and shall be set to zero by the SafetyConsumer. They shall not be evaluated by the SafetyProvider.

The InFlagsType representation in the AddressSpace is defined in Table 15.

Table 15 – InFlagsType dDefinition

|

Attribute |

Value |

|||||

|

BrowseName |

InFlagsType |

|||||

|

IsAbstract |

False |

|||||

|

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Other |

|

|

Subtype of the Byte DataType defined in OPC 10000-3 |

||||||

|

0:HasProperty |

Variable |

0:OptionSetValues |

0:LocalizedText [] |

0:PropertyType |

|

|

|

Conformance units |

||||||

|

SafetySupport |

||||||

The OutFlagsType is a subtype of the Byte DataType with the OptionSetValues Property defined. The OutFlagsType is formally defined in Table 16.

Table 16 – OutFlagsType values

|

Value |

Bit no. |

Description |

|

OperatorAckProvider |

0 |

Operator acknowledgment at the provider, hereby forwarded to the SafetyConsumer, see OperatorAckProvider in the SAPI of the SafetyProvider, 6.3.3.2. |

|

ActivateFSV |

1 |

Activation of fail-safe values by the safety application at the SafetyProvider, hereby forwarded to the SafetyConsumer, see ActivateFSV in the SAPI of the SafetyProvider, 6.3.3.2. |

|

TestModeActivated |

2 |

Enabling and disabling of test mode in the SafetyProvider, hereby forwarded to the SafetyConsumer, see EnableTestMode in the SAPI of the SafetyProvider, 6.3.3.2. |

Bits 3 to 7 are reserved for future use and shall be set to zero by the SafetyProvider. They shall not be evaluated by the SafetyConsumer.

The OutFlagsType representation in the AddressSpace is defined in Table 17.

Table 17 – OutFlagsType dDefinition

|

Attribute |

Value |

|||||

|

BrowseName |

OutFlagsType |

|||||

|

IsAbstract |

False |

|||||

|

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Other |

|

|

Subtype of the Byte DataType defined in OPC 10000-3 |

||||||

|

0:HasProperty |

Variable |

0:OptionSetValues |

0:LocalizedText [] |

0:PropertyType |

|

|

|

Conformance units |

||||||

|

SafetySupport |

||||||

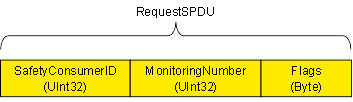

Table 18 shows the definition of the RequestSPDUDataType. The Prefix “In” is interpreted from the SafetyProvider’s point of view and is used in a consistent manner to the parameters of the Method ReadSafetyData (see 6.2.2.3).

Table 18 – RequestSPDUDataType structure

|

Name |

Type |

Description |

|

RequestSPDUDataType |

structure |

|

|

InSafetyConsumerID |

UInt32 |

See corresponding Method argument in Table 7. |

|

InMonitoringNumber |

UInt32 |

See corresponding Method argument in Table 7. |

|

InFlags |

InFlagsType |

See corresponding Method argument in Table 7. |

The representation in the AddressSpace of the RequestSPDUDataType is defined in Table 19.

Table 19 – RequestSPDUDataType definition

|

Attributes |

Value |

||||

|

BrowseName |

RequestSPDUDataType |

||||

|

IsAbstract |

False |

||||

|

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

ModellingRule |

|

Subtype of Structure defined in OPC 10000-3. |

|||||

|

Conformance units |

|||||

|

SafetyPDUs |

|||||

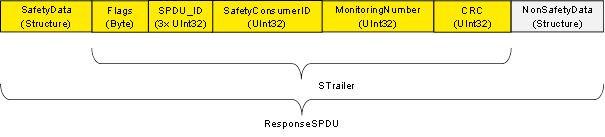

Table 20 shows the ResponseSPDUDataType Structure. The Prefix “Out” is interpreted from the SafetyProvider’s point of view and is used in a consistent manner to the parameters of the Method ReadSafetyData (see 6.2.2.3).

Table 20 – ResponseSPDUDataType structure

|

Name |

Type |

Description |

|

ResponseSPDUDataType |

structure |

|

|

OutFlags |

OutFlagsType |

See corresponding Method argument in Table 7. |

|

OutSPDU_ID_1 |

UInt32 |

See corresponding Method argument in Table 7. |

|

OutSPDU_ID_2 |

UInt32 |

See corresponding Method argument in Table 7. |

|

OutSPDU_ID_3 |

UInt32 |

See corresponding Method argument in Table 7. |

|

OutSafetyConsumerID |

UInt32 |

See corresponding Method argument in Table 7. |

|

OutMonitoringNumber |

UInt32 |

See corresponding Method argument in Table 7. |

|

OutCRC |

UInt32 |

See corresponding Method argument in Table 7. |

[RQ6.7] To define the concrete DataType for the ResponseSPDU (which specifies the concrete DataTypes for SafetyData and NonSafetyData, respectively), proceed as follows: (1) Derive a concrete DataType from the abstract ResponseSPDUDataType. (2) In doing so, add the following fields to the Structure in the given order: (a) First, field OutSafetyData with the concrete Structure DataType for the SafetyData (see 7.2.1.5). (b) Second, field NonSafetyData with the concrete Structure DataType for the NonSafetyData (or a placeholder DataType, see requirement RQ6.8).

[RQ6.8] To avoid possible problems with empty Structures, the dummy Structure NonSafetyDataPlaceholder shall be used as DataType for OutNonSafetyData when no NonSafetyData is used. The DataType Node defining this Structure has a fixed NodeID and contains a single Boolean.

The representation in the AddressSpace of the ResponseSPDUDataType is defined in Table 21.

Table 21 – ResponseSPDUDataType definition

|

Attributes |

Value |

||||

|

BrowseName |

ResponseSPDUDataType |

||||

|

IsAbstract |

True |

||||

|

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

ModellingRule |

|

Subtype of Structure defined in OPC 10000-3 |

|||||

|

Conformance units |

|||||

|

SafetyPDUs |

|||||

Table 22 shows the definition of the NonSafetyDataPlaceholderDataType. The receiver shall not evaluate the value of ‘dummy’.

Table 22 – NonSafetyDataPlaceholderDataType structure

|

Name |

Type |

Description |

|

NonSafetyDataPlaceholderDataType |

Structure |

|

|

Dummy |

Boolean |

Dummy Variable to avoid empty structures. |

Future versions may use different identifiers (such as ReadSafetyDataV2 for the Method when using Client/Server communication or RequestSPDUV2DataType and ResponseSPDUV2DataType for the SPDU DataTypes when using PubSub communication), allowing a SafetyProvider to implement multiple versions of this document at the same time. Hence, the same SafetyProvider can be accessed by SafetyConsumers of different versions.

This document supports sending of the Built-in and Simple DataTypes specified in OPC UA (see OPC 10000-3 and OPC 10000-6) within SafetyData. The supported DataTypes are vendor-specific.

[RQ6.9] Only scalar DataTypes shall be used. Arrays are currently not supported by this document.

The supported maximum length of the SafetyData is vendor-specific but still limited to 1 500 octets. Typical values for the maximum length include 1 octet, 16 octets, 64 octets, 256 octets, 1 024 octets, and 1 500 octets.

[RQ6.10] For controller-like devices, the supported DataTypes and the maximum length of the SafetyData shall be listed in the user manual.

[RQ6.11] For the DataType Boolean, the value 0x01 shall be used for ‘true’ and the value 0x00 shall be used for ‘false’.

It is recommended to send multiple Booleans in separate variables. However, in small devices, it can be necessary to combine a set of 8 Booleans in one Variable for performance reasons. In this case, the DataType Byte can be used.

This document uses the OPC UA services for connection establishment, it poses no additional requirement to these services.